Andheri West, Mumbai, Maharashtra

- GST NO. : 27AAACE3165H1ZS

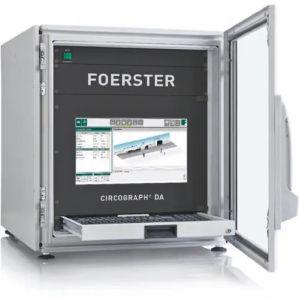

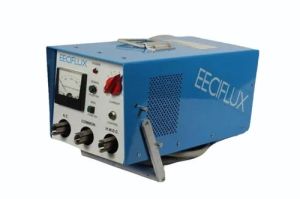

Circoflux Magnetic Flux Leakage Testing Solution

| Business Type | Supplier |

| Type Of Testing Machines | Magnetic Flux Leakage |

| Brand | Institut Dr. Foerster GmbH & Co. KG,Germany |

| Model Name/Number | Circoflux DS and Sensor System |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

NON-DESTRUCTIVE CRACK TESTING WITH ROTATING PROBE

The CIRCOFLUX test system is used for the non-destructive surface testing of ferromagnetic steel bars using the magnetic flux leakage method in accordance with standard EN 10221. This method is the most sensitive surface testing method for longitudinal, crack-like defects in hot-rolled ferromagnetic steel bars. The CIRCOFLUX sensor system therefore replaces subjective testing methods such as the magnetic powder test (magnetic crack detection) and visual checks, which are difficult to document and reproduce.

The available sensor systems cover a material diameter range from approx. 10 to 180 mm. FOERSTER''s long-standing experience in this field ensures high operating reliability. The modular design of the test electronics is also ideally suited to meet future demand for ever increasing defect detection sensitivity.

Your advantages at a glance

- Standardized hardware and software for all FOERSTER test instruments simplifies the handling

- Easy operation using modern touchscreen display

- Network integration in existing production and quality systems

- Integrated diagnostic and documentation function for compiling your test results

- Relational database for high data integrity and open port to other applications

- Maximum detection sensitivity of defects from 0.1 mm depth on ferromagnetic rods with hot-rolled surface

- Test material diameter from 10 - 180 mm

- Pivoting test levers also tolerate non-straight material and protect against damage to or destruction of the test elements

- Central adjustment to the test diameter minimizes the risk of adjustment errors

- Automatic dimensions adjustment reduces setting up time and increases productivity

Technical Data

|

Sensor system: |

Rotating sensor system with two opposite test heads |

|

Max. number of measurement channels: |

24 |

|

Max. throughput speed: |

4 m/s |

|

Magnetizing current frequency: |

6 kHz (Ro75, Ro100, Ro180) or 7.5 kHz (Ro130) |

|

Testing error: |

depth 0.15 mm x width 0.1 mm |

|

Diameter ranges: |

10 - 75 mm (Ro 75); 10 - 100 mm and 15 - 105 mm (Ro 100); 15 - 130 mm (Ro 130); 20 - 180 mm (Ro 180) |

|

Setting time (with roller guide): |

approx. 3 minutes (Ro 75, Ro 100, Ro 130); approx. 5 minutes (Ro 180) |

|

Maximum rotational speeds: |

2,400 rpm (Ro 75); 1,500 rpm (Ro 100 and Ro 130); 960 rpm (Ro 180) |

|

Maximum throughput speed: |

2 m/s (Ro 75); 3.75 m/s (Ro 100); 4 m/s (Ro 130); 2.4 m/s (Ro 180) |

Looking for "Circoflux Magnetic Flux Leakage Testing Solution" ?

Explore More Products