Andheri West, Mumbai, Maharashtra

- GST NO. : 27AAACE3165H1ZS

Eddy Current Component Testing Machine

Leading Manufacturers, Exporters, Wholesaler and Importer of Koerzimat 1.097HCJ / J-H Measuring System, Magnatest D Eddy Current Material Mix Up Test Instrument, Magnatest ECM Eddy Current Material Mix Up Test Instrument, Statograph CM+/CM Eddy Current Crack Detection Machine and ZMAG CM Demagnetization Unit from Mumbai.

MOQ : 1 Unit

| Business Type | Supplier |

| Voltage | 100 - 240 VAC,50/60 Hz |

| Type of Testing Machines | coercivity HCJ, hysteresis J(H) and relative permeability micror(H) measurement |

| Brand Name | Institut Dr. Foerster GmbH & Co. KG, Germany |

| Model Name/Number | KOERZIMAT 1.097 HCJ/J-H |

| Measuring Range | HCJ: 0 - 100 kA/m And micror(H): 100 - 2500 |

| Magnetization field strength | up to 450 kA/m |

| Sensor | Foerster probes (fluxgates) |

| Standards | ASTM B887, EN IEC 60404-7:2020 |

| Additional Information |

Preferred Buyer From

| Location | Worldwide |

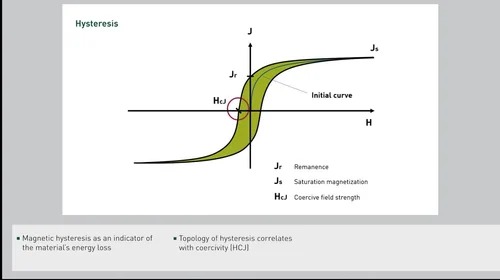

Material evaluation based on magnetic properties

Magnetic values such as coercivity HCJ correlate with numerous important process parameters and material properties in the production of sintered hard metals and powder-metallurgical components. The KOERZIMAT 1.097 HCJ measuring system by FOERSTER facilitates the accurate, automatic, and fast measurement of the coercivity HCJ. The largely geometry-free measurement is particularly suitable for testing samples with complex shapes. The extension module J-H measurement offers the possibility to determine the complete J-H Hysteresis on soft magnetic steel incl. the initial curve.

The applications of the KOERZIMAT include the control of the sintering level and particle size of hard metals and the quality control of metallic powders for the production of magnets and hard metals. The unit can also be used for monitoring the quality of the annealing and the mechanical stress state of soft-magnetic components (SMC) and for controlling electromechanical components in the electronics, automotive, computer, and clock sectors.

Your advantages at a glance:

• Determination of coercivity in accordance with IEC 60404-7

• Determination of hysteresis J(H) for soft magnetic steel bars

• Determination of relative permeability µr(H) for soft magnetic steel bars

• PC-controlled measuring system

• Geometry-free measurement

• Lightweight, extremely compact design

• Software for controlling individual and series measurements

• Database for collecting measurement data and parameter sets

• Customer-specific reports

• Remote port for automation, data access, etc.

Technical Data:

KOERZIMAT 1.097 HCJ/J-H

Measurement range: HCJ 0 – 100 kA/m

µr(H) 100 – 2500

Magnetization field strength: up to 450 kA/m

Homogenous field area: 170 x 40 mm (LxD), coil 40

120 x 60 mm (LxD), coil 60

Measurement uncertainty: 1 % of measured value

Sensor elements: Foerster probes (fluxgates)

Power supply: 100 – 240 VAC, 50/60 Hz

MOQ : 1 Unit

| Business Type | Supplier |

| Type Of Testing Machines | EDDY CURRENT MATERIAL SORTING AND HARDNESS TESTER |

| Brand | Institut Dr. Foerster GmbH & Co. KG, Germany |

| Model Name/Number | Magnatest D |

| Stimulation | Mono-frequency, Multi-frequency |

| Excitation frequency | 2 Hz to 128 kHz, 17 levels |

| Throughput | depending on excitation frequency, approx. 10 items at 1 kHz |

| Test Resolution | Manual, External, Internal, Crosshairs |

| Sorting Threshold | Circle, Ellipse, Rectangle (manual Areas), Box Regression |

| Sorting Process Testing | Group Analysis |

| Additional Information |

Preferred Buyer From

| Location | Worldwide |

The FOERSTER MAGNATEST D 3.623 is an electronic instrument for non-destructive testing of conductive materials for their different magnetic and/or electrical properties.

It is ideal for testing mass-produced components (such as fasteners, shafts, studs, rings, valves, sprockets, gears, forged parts, cast parts, machined parts, sintered parts, and more) for differences in:

- Alloy Composition

- Heat treatment

- Grain Structure

- Hardness

- Case Depth

- Dimensional and Geometrical Differences

Features & Benefits:

- PC controlled electromagnetic test electronics for fully automated and rapid testing of every individual component produced (can also be employed manually and offline)

Automated micro-structure and hardness testing with coils and probes:

The sensors for testing material properties are available as coils or probes, depending on the material concerned. A broad range of standard testing coils and standard testing probes is available for the various MAGNATEST test instruments. In addition, we offer individually adapted customized solutions for special sizes or geometries.

MOQ : 1 Unit

| Business Type | Supplier |

| Type Of Testing Machines | EDDY CURRENT MATERIAL SORTING AND HARDNESS TESTER |

| Brand | Institut Dr. Foerster GmbH & Co. KG, Germany |

| Model Name/Number | Magnatest ECM |

| Operating Frequency | 2 Hz to 128 kHz, 17 levels |

| Throughput | Depending On Excitation Frequency, Approx. 10 Items At 1 Khz |

| Test Resolution | Manual, External, Internal |

| Sorting Threshold | Circle, Ellipse, Rectangle |

| Stimulation | Mono-frequency |

| Additional Information |

Preferred Buyer From

| Location | Worldwide |

MAGNATEST ECM is the line-ready compact module for simple testing tasks. The unit simply and reliably performs testing tasks such as material mix and deviation measurements as well as deviations in surface hardness and case-hardening depth. MAGNATEST ECM is designed to be used as the core component in quality assurance systems during series production and for installation in production systems. It is particularly suitable for applications that primarily focus on profitability and less on multiple functions.

- Low-cost eddy-current module for non-destructive testing using the magneto-inductive method.

- Genuine magneto-inductive testing by evaluation of harmonics.

- Test parameters variable over wide ranges.

- Simple operation.

- Test pieces sorted in two groups: o.k. / n.o.k.

- One-dimensional display of measured value by LED bar graph.

- Key-operated switch for locking operating functions.

Technical Data

|

Excitation frequency: |

2 Hz to 128 kHz, 17 levels |

|

Throughput: |

depending on excitation frequency, approx. 10 items at 1 kHz |

|

Test resolution: |

manual, external, internal |

|

Sorting threshold: |

circle, ellipse, rectangle |

|

Stimulation: |

mono-frequency |

MOQ : 1 Unit

| Business Type | Supplier |

| Type Of Testing Machines | EDDY CURRENT CRACK DETECTION |

| Brand | Institut Dr. Foerster GmbH & Co. KG, Germany |

| Model Name/Number | STATOGRAPH CM+/CM |

| Excitation frequency: | 1 kHz, 3 kHz, 10 kHz, 30 kHz, 100 kHz, 300 kHz, 1 MHz, 3 MHz, 10 MHz |

| Mains Connection: | 85 - 265 V, 47 - 63 Hz |

| Sensor | Differential or absolute sensor |

| High-pass, Low-pass Filter | 1 Hz to 56 kHz (28 levels) |

| Interface | Profinet, Digital I/O |

| Additional Information |

Preferred Buyer From

| Location | Worldwide |

Compact and robust, the STATOGRAPH CM+ / CM consists of powerful hardware and software to guarantee reliable inspections. Both STATOGRAPH modules are network-compatible and can thus be operated via a tablet or smartphone. Production line status can therefore be checked anytime and anywhere, meaning that immediate corrective action can be taken if necessary. Test parameters and other settings can be captured and adjusted on the fly.

The STATOGRAPH CM+ also has a touch screen for use directly in the line.

On the STATOGRAPH CM, a multi-color LED tells the device status with a quick glance into the control cabinet.

SENSOR TECHNOLOGY:

All existing probes can be connected as usual to the new STATOGRAPH CM+ / CM modules. A broad portfolio of standard and special-purpose probes is available. This means that, with FOERSTER, you’re optimally prepared for any challenge.

Standard probes:For crack testing on components, stationary differential-eddy-current probes are usually installed directly in the test station. These have a very high test sensitivity and generate reproducible test results.

Special probes:Components with complex geometries require special test solutions. For this reason, FOERSTER’s probe portfolio includes, among others, angled sensors and its FLEXPROBES, which are flexible probes that can be adapted to the unique geometry of the test piece.

In addition, we can also develop customer-specific probes for high-resolution testing.

MOQ : 1 Unit

| Business Type | Supplier |

| Model Name/Number | ZMAG CM |

| Brand | Institut Dr. Foerster GmbH & Co. KG, Germany |

| Diameter | 30 mm to 220 mm (various models). Customised sizes also available. |

| Size/Dimension | 211 x 317 x 133mm |

| Voltage | 230 VAC, 50 / 60 Hz |

| Demagnetizazion | Pulse Method allows a greater penetration of the component than at a constant frequency |

| Interface | I / O interface for control available. Alternatively, manual operation is possible. |

| Additional Information |

Preferred Buyer From

| Location | Worldwide |

Effective demagnetization via the pulse method

Magnetized components can lead to interference signals during crack or microstructure testing with eddy current component conditions, therefore resulting in false readings.

To avoid this, FOERSTER offer a powerful demagnetization unit: the ZMAG CM. The pulse method used enables high penetration depth to demagnetize the components effectively and promptly. The Siemens control and pre-configuration allows an easy integration of the unit into your production process. Thus, your process quality and reliability can be significantly increased.

Your advantages at a glance

• Flexible spool size: There are four spool sizes available with 30/75/110/220 mm. Other sizes on request.

• It can be automated: I / O interface for control available. Alternatively, manual operation is possible.

• Plug & Play: Pre-configured degaussing: You don't have to set anything; you can start right away.

• High demagnetization performance: Powerful pulse shape for effective demagnetization.

• Pulse method: The pulse method allows a greater penetration of the component than at a constant frequency.

Applications:

1. Elimination of misinterpretations

2. False signals during microstructure testing

3. Magnetic particle testing

4. Magnetic adhesion of metal chips

5. Coating processes

6. Compliance with manufacturing standards