Andheri West, Mumbai, Maharashtra

- GST NO. : 27AAACE3165H1ZS

Eddy Current Semi Finished Material Testing

Leading Manufacturers, Exporters, Wholesaler and Importer of Circoflux Magnetic Flux Leakage Testing Solution, Circograph CI Eddy Current Crack Detection System, Circograph DA Eddy Current Crack Detection Solution, Defectomat CI Eddy Current Testing System for Crack Detection, Defectomat DA Eddy Current Testing Solution, Defectomat ECM Eddy Current Tester and Defectovision Ir Inductive Heat Flux Thermography from Mumbai.

MOQ : 1 Piece

| Business Type | Supplier |

| Type Of Testing Machines | Magnetic Flux Leakage |

| Brand | Institut Dr. Foerster GmbH & Co. KG,Germany |

| Model Name/Number | Circoflux DS and Sensor System |

| Max. throughput speed | 4 m/sec |

| Diameter range | 10 - 75 mm (Ro 75); 10 - 100 mm and 15 - 105 mm (Ro 100); 15 - 130 mm (Ro 130); 20 - 180 mm (Ro 180) |

| Sensor Type | Rotating sensor system with two opposite test heads |

| Max. number of measurement channels | 24 |

| Magnetizing current frequency | 6 kHz (Ro75,Ro100,Ro180) or 7.5 kHz (Ro130) |

| Maximum rotational speeds | 2,400 rpm (Ro 75); 1,500 rpm (Ro 100 and Ro 130); 960 rpm (Ro 180) |

Preferred Buyer From

| Location | Worldwide |

NON-DESTRUCTIVE CRACK TESTING WITH ROTATING PROBE

The CIRCOFLUX test system is used for the non-destructive surface testing of ferromagnetic steel bars using the magnetic flux leakage method in accordance with standard EN 10221. This method is the most sensitive surface testing method for longitudinal, crack-like defects in hot-rolled ferromagnetic steel bars. The CIRCOFLUX sensor system therefore replaces subjective testing methods such as the magnetic powder test (magnetic crack detection) and visual checks, which are difficult to document and reproduce.

The available sensor systems cover a material diameter range from approx. 10 to 180 mm. FOERSTER''s long-standing experience in this field ensures high operating reliability. The modular design of the test electronics is also ideally suited to meet future demand for ever increasing defect detection sensitivity.

Your advantages at a glance

- Standardized hardware and software for all FOERSTER test instruments simplifies the handling

- Easy operation using modern touchscreen display

- Network integration in existing production and quality systems

- Integrated diagnostic and documentation function for compiling your test results

- Relational database for high data integrity and open port to other applications

- Maximum detection sensitivity of defects from 0.1 mm depth on ferromagnetic rods with hot-rolled surface

- Test material diameter from 10 - 180 mm

- Pivoting test levers also tolerate non-straight material and protect against damage to or destruction of the test elements

- Central adjustment to the test diameter minimizes the risk of adjustment errors

- Automatic dimensions adjustment reduces setting up time and increases productivity

Technical Data

|

Sensor system: |

Rotating sensor system with two opposite test heads |

|

Max. number of measurement channels: |

24 |

|

Max. throughput speed: |

4 m/s |

|

Magnetizing current frequency: |

6 kHz (Ro75, Ro100, Ro180) or 7.5 kHz (Ro130) |

|

Testing error: |

depth 0.15 mm x width 0.1 mm |

|

Diameter ranges: |

10 - 75 mm (Ro 75); 10 - 100 mm and 15 - 105 mm (Ro 100); 15 - 130 mm (Ro 130); 20 - 180 mm (Ro 180) |

|

Setting time (with roller guide): |

approx. 3 minutes (Ro 75, Ro 100, Ro 130); approx. 5 minutes (Ro 180) |

|

Maximum rotational speeds: |

2,400 rpm (Ro 75); 1,500 rpm (Ro 100 and Ro 130); 960 rpm (Ro 180) |

|

Maximum throughput speed: |

2 m/s (Ro 75); 3.75 m/s (Ro 100); 4 m/s (Ro 130); 2.4 m/s (Ro 180) |

MOQ : 1 Piece

| Business Type | Supplier |

| Type of Testing Machines | Eddy Current Crack Detection Machine |

| Brand | Institut Dr. Foerster GmbH & Co. KG, Germany |

| Model Name/Number | Circograph CI |

| Operating Frequency | 30 kHz - 1 MHz |

| Test material | Ferromagnetic, austenitic, and non-ferromagnetic material |

| Max. throughput | 3 m/s during continuous testing |

| Defect Display | From 0.030 Mm At Ro 20 / Ro 35 |

| Sensor system | Rotating sensor system with a maximum of two (Ro 20 and Ro 35) opposite test heads |

| Additional Information |

Preferred Buyer From

| Location | Worldwide |

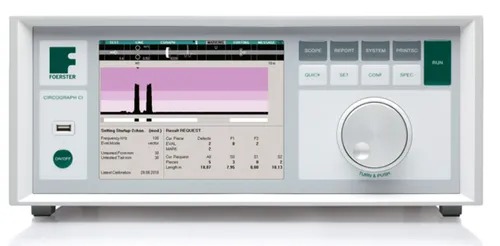

Compact test system for longitudinal surface defects

The CIRCOGRAPH CI combines a compact design with intuitive operation in one high-precision rotating test system. The CIRCOGRAPH CI features a user-friendly operation unit as well as easy "Turn-and-Push" rotary switch. The 2-channel system can be adjusted optimally to suit your test tasks thanks to a large range of different rotating heads. Longitudinal defects in the material surface can thus be detected from depths as low as 30 µm.

Your advantages at a glance:

- Compact design

- Simple operation thanks to integrated operation unit and "turn-push" operation

- Universal testing system, can be adapted to individual applications and requirements

- 2-channel test system

- Seamless, continuous testing

- Defect depth resolution from 30 µm

MOQ : 1 Unit

| Business Type | Supplier |

| Model Name/Number | Circograph DA |

| Instrument Type | Eddy Current Crack Detector For Bright Material |

| Type Of Testing Machines | Eddy Current Crack Detection Machine |

| Industry Type | Manufacturing |

| Brand | Institut Dr. Foerster GmbH & Co. KG |

| Operating Frequency | Operating Frequency |

| Measurement Channels | Up to 256 test channels in real time (without multiplexing) |

| Filtering process | Digital speed shift filter: dynamic adjustment of the filter's position to the test speed |

| Testing speed | Max. 6 m/s |

| Sensor monitoring | Broken wires, overload, automatic sensor recognition |

| Additional Information |

Preferred Buyer From

| Location | Worldwide |

Multi-Channel Eddy Current Testing at the Highest Level

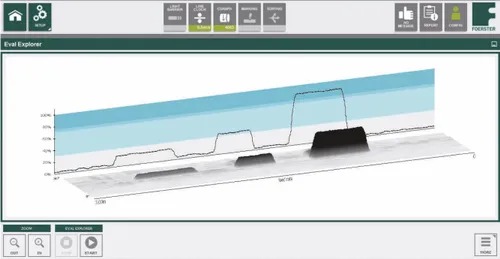

With the CIRCOGRAPH DA, FOERSTER sets new standards in non-destructive eddy current testing of long products such as tubes, bars and wires for longitudinally oriented surface defects. CIRCOGRAPH DA offers unsurpassed reproducibility at high test speeds by combining advanced digital electronics with sophisticated system architecture. Digitization takes place directly at the sensor. In order to reduce possible interferences from the outside, the signal paths of the analog test signals have been reduced to a minimum. Equipped with the latest technology and intelligent details, the CIRCOGRAPH DA can also be integrated into existing production lines.

Better Overview by Visualization of the Test Signals as C-Scan

The new product generation CIRCOGRAPH DA enables displaying of the test signals as a C-Scan. The signal sequence is shown as usual as the sum signal over the distance. The defect position is displayed in the longitudinal direction. Additionally, in the C-Scan view, the signals are now also displayed in the circumferential position. The operator is thus given a better overview of where and, above all, how the defect propagates on the material surface.

Your advantages at a glance

- Compact and robust construction for industrial applications

- Future-proof due to modular construction, ready for future expansion

- Optional extension with DEFECTOMAT sensor systems

- Up to 256 measurement channels without multiplex operation

- Digitization right at the sensor

- Test frequencies continuously adjustable from 30 kHz to 1 MHz in 100 Hz steps

- Digital speed shift filter: Filters move along dynamically with the speed

- CIRCOGRAPH rotating heads allow for contactless testing with test speeds up to 6 m/s

MOQ : 1 Unit

| Business Type | Supplier |

| Type Of Testing Machines | Eddy Current Crack Detection Machine |

| Brand | Institut Dr. Foerster GmbH & Co. KG, Germany |

| Model Name/Number | Defectomat CI |

| Usage | Industrial |

| Industrial | max. dynamic range 102 dB |

| Operating Frequency | 1, 3, 6, 10, 12, 15, 20, 30, 60, 100, 300, 1,000 kHz - optional additional frequencies |

| Test speed | max. 150 m/s |

| Filtering process | manual, 12 levels, 1 Hz - 16 kHz |

| Measurement channels | Max. 2 independent channels, differential or static operation |

| Additional Information |

Preferred Buyer From

| Location | Worldwide |

2-channel base module for almost all requirements

One of the most popular eddy current test instruments in the world with an unrivaled compact design. The DEFECTOMAT CI features an operation unit as well as easy "Turn and Push" operation. The evaluation electronic equipment also comes with two optional, fully operational measurement channels. It also has a filter tracking setting, excitation frequencies from 1 to 1,000 kHz, and a sector signal analysis function.

Your advantages at a glance

- Optional full 2-channel analysis, Diff/Abs, Diff/Diff, Diff/Ferromat

- 12 excitation frequencies from 1 to 1,000 kHz

- Filter tracking according to test speed

- Precision marking in exact location

- Sector signal analysis with 2 trigger levels

- Analogue output

- State-of-the-art computer technology

- Full network integration

- Quick and easy with "Turn and Push"

- Password-protected operating level

- Clear color display

- Visualization of the testing process

- Continuous display of the key test parameters

MOQ : 1 Unit

| Business Type | Supplier |

| Type Of Testing Machines | Eddy Current Crack Detection Machine |

| Industry Type | Manufacturing |

| Usage/Application | Industrial |

| Brand | Institut Dr. Foerster GmbH & Co. KG, Germany |

| Model Name/Number | Defectomat DA |

| Operating Frequency | 1 kHz - 1 MHz (endlessly adjustable) |

| Sensor Monitoring | Broken wires, overload, automatic sensor recognition |

| Amplification | Max. Dynamic Range 126 Db |

| Measurement Channels | Up to 16 TEST SYSTEM DA modules with 16 measurement channels each |

| Filtering process | Digital speed shift filter; filters move along dynamically with the speed |

| Testing Speed | max. 150 m/s |

| Additional Information |

Preferred Buyer From

| Location | Worldwide |

The DEFECTOMAT DA evaluation electronic equipment by FOERSTER has a combination of key features that as a whole are designed to provide consistent productivity and process reliability. Fully digital and fitted with innovative operating software, this system with unequalled specifications combines the latest technology for non-destructive eddy current testing of tubes, rods, and wires. Experience the eddy current technology of the future today.

Your advantages at a glance

- Compact and robust construction for industrial applications

- Future-proof due to modular construction, ready for future expansion

- Up to 256 measurement channels without multiplex operation

- Option to connect up to 16 TEST SYSTEM DA modules (with 16 measurement channels each)

- Fully digital evaluation electronic equipment

- Excitation frequencies from 1 kHz to 1 MHz, endlessly adjustable

- 126 dB amplification

- Digital speed shift filter: Filters move along dynamically with the speed

- High test speed up to 150 m/s

MOQ : 1 Unit

| Business Type | Supplier |

| Type Of Testing Machines | Eddy Current Crack Detection Machine |

| Brand | Institut Dr. Foerster GmbH & Co. KG, Germany |

| Model Name/Number | Defectomat ECM |

| Operating Frequency | 10 kHz, optional frequency module, max. 8 levels |

| Measurement Channels | 1, Optional Additional Absolute Channel |

| Filtering Process | HP+TP, manual adjustment, 25 levels, 1 Hz - 16 kHz |

| Amplification | max. dynamic range 102 dB |

| Test Speed | Max. 150 M/s |

| Additional Information |

Preferred Buyer From

| Location | Worldwide |

Affordable and compact quality assurance solution

The modular DEFECTOMAT ECM is extremely compact, yet features many options for integration in popular production systems. Designed for simple operation, the compact test instrument performs Yes/No filtering of the test materials. The module has an integrated port for expanding the line functionality, e.g. for a marking, sorting, and crosscutting device. In addition, the test results can be logged, statistically analyzed, and archived via a connected master computer.

Your advantages at a glance

- Module for eddy current testing with through-type coils, reduced to its essential features

- Various fixed frequency modules available

- Multiple frequency module as optional extra

- Simple controls

- Unidimensional signal display with LED bar graph

- Yes/No filtering

- Simple integration in control cabinets

- Optional expansion for additional requirements such as phase adjuster, absolute channel, output amplifier, oscilloscope, RS-232 port for parameter adjustment

- Adapter for saving the configuration data for quick refitting

MOQ : 1 Unit

| Business Type | Supplier |

| Test products | Round and square ferromagnetic steel billets |

| Manufacturer | Institut Dr. Foerster GmbH & Co. KG, Germany |

| Diameter / edge length | 50 - 300 mm |

| Max. test speed | 1.5 m/s |

| Testing method | Inductive heat flux thermography |

| Untested ends | 5 mm |

| Additional Information |

Preferred Buyer From

| Location | Worldwide |

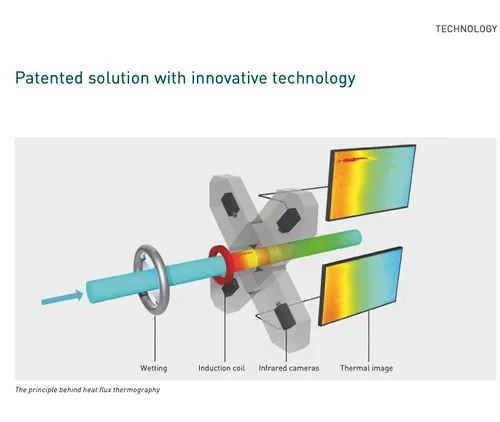

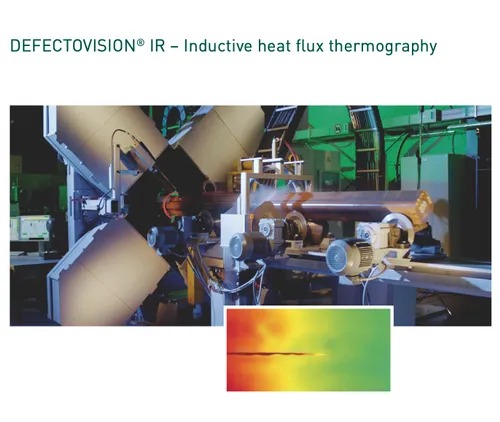

Innovative testing with FOERSTER

The DEFECTOVISION IR system is an addition to FOERSTER's core competence, the non-destructive testing of semi-finished metal products. All around the world, more than 6.5 million tons of steel have been tested safely and efficiently by now with our latest technology.

The automatic infrared technology applied by FOERSTER provides new approaches for previously impossible testing tasks.

Inductive heat flux thermography facilitates the testing of entire surfaces of hot-rolled steel billets and tubes with round, square, or rectangular cross-sections as well as rails and profiles. Flat surfaces as well as exterior and interior radiuses are tested fully and reproducibly. All but a few millimetres of the ends of the materials are also covered by the surface test.

Technical Data:

Test products: Round and square ferromagnetic steel billets

Diameter / edge length: 50 – 300 mm

Test product length: min. 4 m

Max. test speed: 1.5 m/s

Untested ends: type 5 mm

Minimum defect depth: 0.3 mm

Minimum defect length: 10 mm

Your advantages at a glance:

• Fully automatic testing of round and profiled steel billets, tubes, and rails

• Adjustable defect thresholds for targeted depth selection

• Reduces repair costs by suppressing incorrect warnings

• Comprehensive electronic documentation of the test results

• Integration in existing production and quality systems

• Contactless and non-wearing technology

• Compact design for integration in existing production lines

• High throughput

• Test fully covers the entire material surface

• Detection of even the smallest material defects